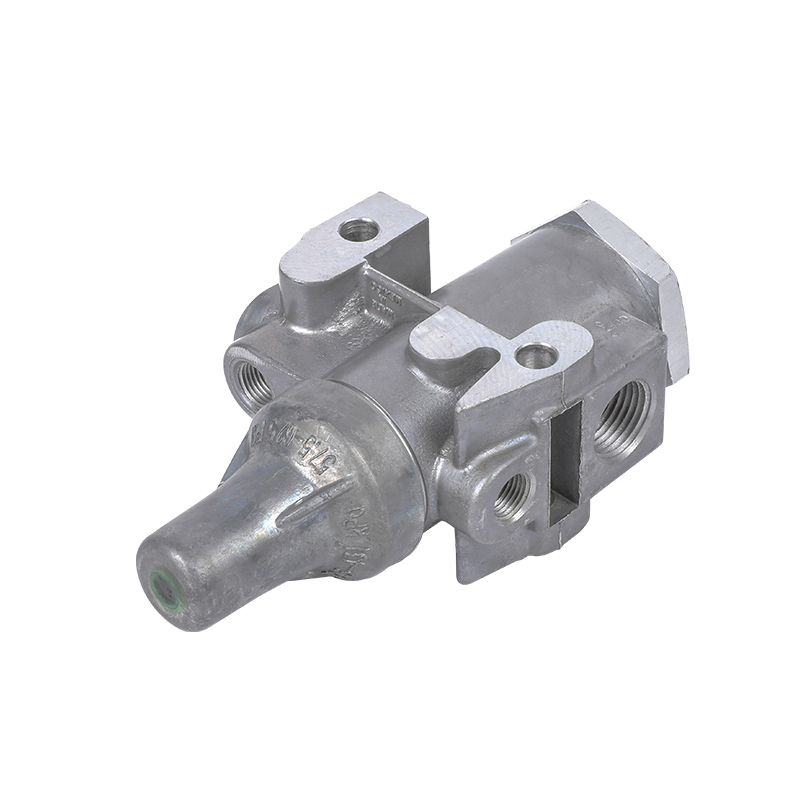

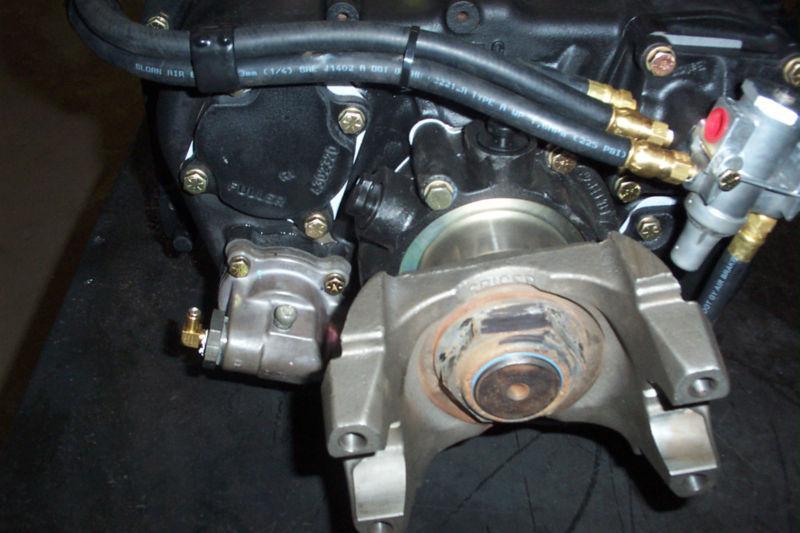

As core components for fluid motion control, our high-precision spools, valve stems, and shafts directly determine a system's responsiveness and efficiency. Through micron-level machining, specialized surface treatment, and full-process SPC control, we ensure our products offer considerable wear and anti-fatigue properties in demanding conditions.

These core parts are designed to help your equipment achieve higher energy efficiency, reduce leakage, and support extended maintenance intervals, providing essential support for overall performance and reliability.

- The Core to Micron-Level Motion Control Accuracy: With cylindricity ≤0.0025mm and diameter tolerance ±0.0025mm, our parts form the foundation for fast system response and precise positioning.

- Designed for High Wear Resistance & Long Life: Advanced heat treatment and surface coating technologies significantly increase surface hardness and wear resistance for high-frequency reciprocating motion.

- Ensure High Consistency in Mass Production: Our Statistical Process Control (SPC) system is designed to maintain tight quality standards, ensuring part-to-part and batch-to-batch uniformity that supports the stability of your production line.

- Data-Driven, Full-Process Accuracy Verification: Relies on professional equipment like CMMs and cylindricity testers to provide objective, traceable data reports for micron-level precision.

- Directly Boost System Efficiency & Reliability: Precise fit and low-friction characteristics help minimize internal leakage and energy loss, making them key to optimizing overall system performance.

English

English

中文简体

中文简体