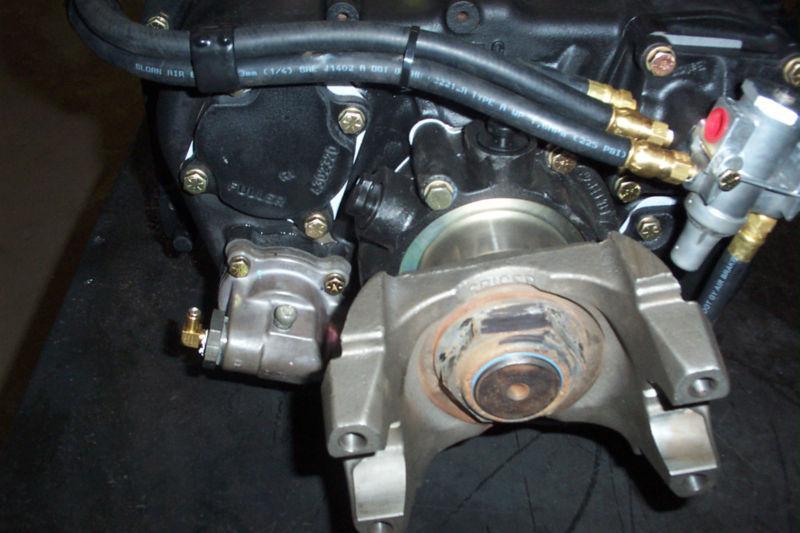

When the slave valve drives the cylinder to control the high and low speed ratio of the vehicle transmission, it usually does not change the gear combination or transmission ratio directly through the piston movement of the cylinder, but controls the relevant hydraulic or pneumatic system to affect the gear shift mechanism of the transmission.

As an actuator, the cylinder can convert the energy of the gas source into mechanical energy. In the transmission control system, the cylinder usually realizes a certain mechanical action through the drive of the slave valve. The slave valve receives a signal from the control system (such as ECU) and controls the intake or exhaust of the cylinder according to the signal instruction.

When the slave valve is opened, the gas source (such as compressed air) is allowed to enter one side of the cylinder to push the piston to move; when the slave valve is closed, the gas in the cylinder is discharged through the exhaust port and the piston is reset.

The cylinder is connected to the gear shift mechanism of the transmission through some mechanical connection (such as connecting rod, rocker arm, etc.). When the cylinder piston moves, the mechanical connection drives the gear shift mechanism to act, such as selecting different gears or changing gear combinations. The control system (such as ECU) calculates the appropriate gear position of the gearbox based on information such as vehicle speed, rotation speed, throttle opening, and driver needs such as acceleration, deceleration, and shifting. The control system converts the gear position information into a control signal and sends it to the slave valve. By controlling the opening and closing of the slave valve, the piston movement of the cylinder is controlled, and finally the high and low speed ratio control of the gearbox is realized.

In short, when the slave valve drives the cylinder to control the high and low speed ratio of the vehicle gearbox, it controls the piston movement of the cylinder and then affects the gearshift mechanism of the gearbox through mechanical connection. This whole process requires precise calculation and control of the control system to ensure that the gearbox can select appropriate gear under different working conditions, so as to achieve an efficient and smooth driving experience. It should be noted that the specific control method and mechanical structure may vary depending on the vehicle model and gearbox type. Therefore, in practical applications, detailed analysis and design are required according to the specific vehicle and gearbox.

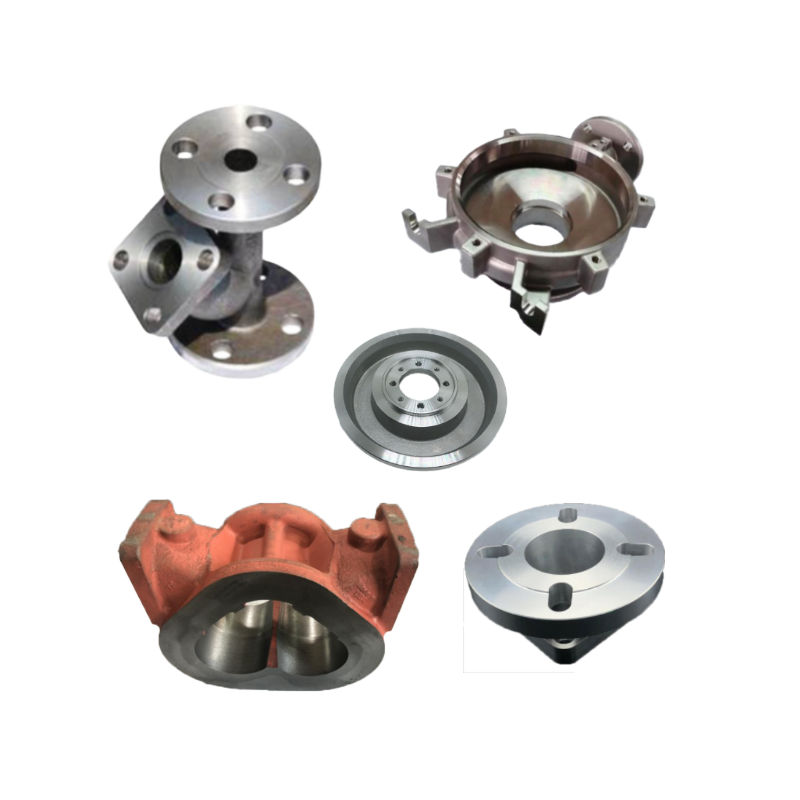

ProductsWe specialize in the precision manufacturing of core components for industrial equipment, offering a range of products including transmission pneumatic control valves, precision-machined components from various formed blanks, high-precision valve stems/shafts, and high-performance mechanical base parts.

ProductsWe specialize in the precision manufacturing of core components for industrial equipment, offering a range of products including transmission pneumatic control valves, precision-machined components from various formed blanks, high-precision valve stems/shafts, and high-performance mechanical base parts.

English

English

中文简体

中文简体