The

slave valve assembly stands as a cornerstone within hydraulic systems, facilitating precise control and fluid regulation essential for various industrial applications. To comprehend its significance fully, one must delve into its key features and operational mechanics, unraveling the intricate components that enable seamless functionality.

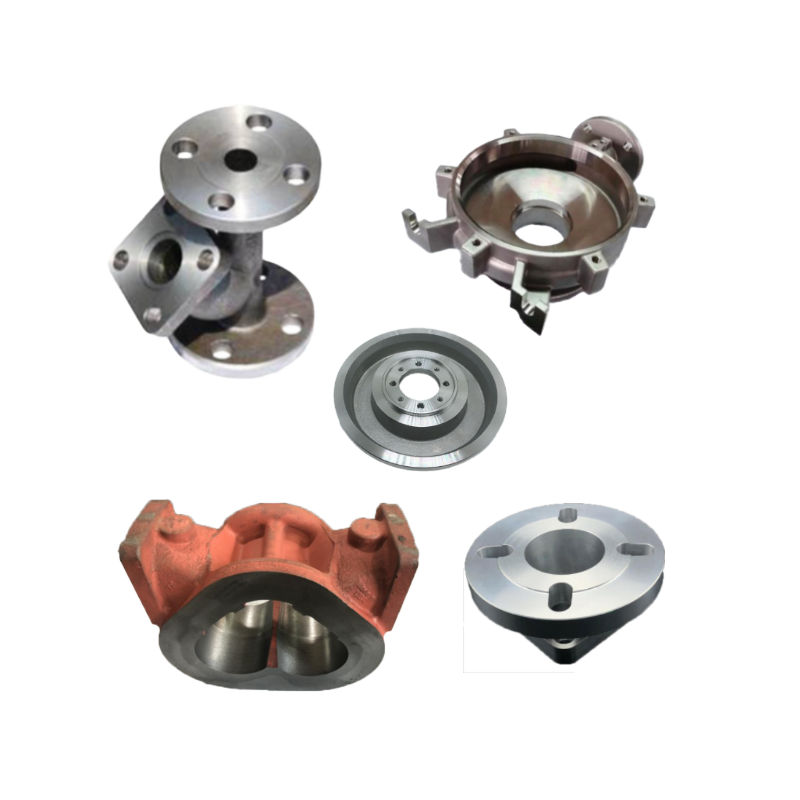

At its core, the slave valve assembly comprises a series of meticulously engineered components designed to regulate the flow of hydraulic fluid within a system. These components typically include valves, actuators, pistons, and control mechanisms, each playing a crucial role in the assembly's operation. The assembly's design emphasizes precision and reliability, ensuring consistent performance even under demanding operating conditions.

One of the primary features of the slave valve assembly is its ability to regulate fluid flow with exceptional accuracy. This precision is achieved through the integration of finely calibrated valves and actuators, which work in tandem to modulate the flow of hydraulic fluid in response to external inputs. Whether controlling the movement of heavy machinery or directing the flow of fluids in industrial processes, the slave valve assembly's precise regulation capabilities are indispensable.

The operational mechanics of the

slave valve assembly are characterized by a delicate balance between control and responsiveness. The assembly's actuators, often powered by hydraulic pressure, translate input signals into precise movements, adjusting valve positions to achieve the desired flow rates. This dynamic responsiveness enables real-time adjustments, allowing the system to adapt to changing operating conditions swiftly.

The slave valve assembly's design incorporates features aimed at enhancing efficiency and reliability. Advanced materials and engineering techniques are employed to minimize friction, reduce wear and tear, and maximize durability. Additionally, built-in safety mechanisms and fail-safe systems ensure uninterrupted operation, mitigating the risk of costly downtime and potential hazards.

In industrial settings, the slave valve assembly plays a pivotal role in optimizing process efficiency and productivity. By precisely controlling the flow of hydraulic fluid, it enables seamless operation of machinery and equipment, minimizing waste and maximizing output. Whether regulating pressure, directing flow, or facilitating precise movements, the assembly's contribution to industrial processes cannot be overstated.

The versatility of slave valve assemblies allows for their integration into a wide range of applications across various industries. From manufacturing and construction to aerospace and automotive sectors, these assemblies find utility in diverse settings where hydraulic systems are employed. Their adaptability and reliability make them indispensable components in modern industrial machinery and equipment.

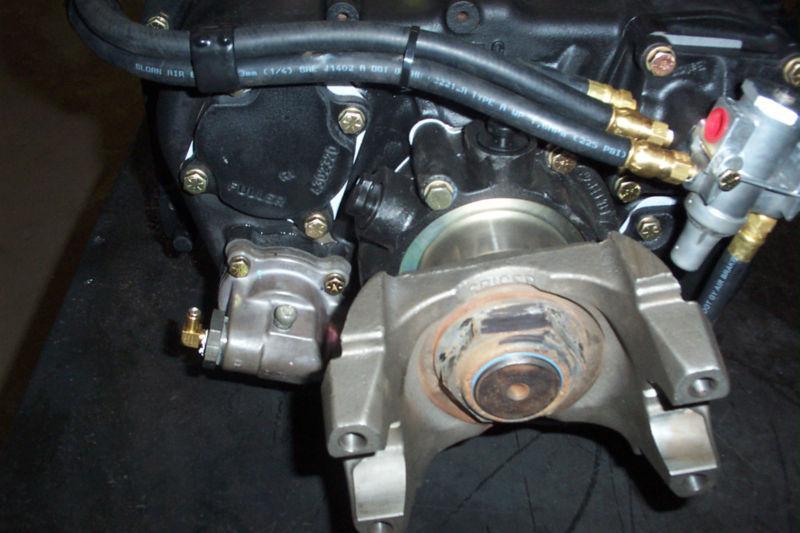

Slave valve assembly A-5000--- Prevents the transmission from becoming stuck in a high or low ratio

--- Replacement restores full functionality to the transmission

--- Easy to install - no special tools necessary for installation

--- This part has undergone Vehicle Try-on testing to meet product standards and quality

English

English

中文简体

中文简体